What Causes Damage to Cement Render?

Cement render is a popular choice for both aesthetic appeal and protection of building exteriors. However, like any building material, it can suffer damage over time. Understanding the causes of this damage is essential for maintaining the integrity and appearance of your property.

Environmental Factors

Weather Conditions

Exposure to various weather conditions is a significant factor in the degradation of cement render. Prolonged exposure to rain, wind, and UV rays can lead to the surface becoming brittle and cracking. In regions with cold climates, freeze-thaw cycles can cause the render to expand and contract, resulting in fissures and even detachment from the substrate.

Moisture Infiltration

Water is one of the most common causes of damage to cement render. Moisture can penetrate through cracks or unsealed areas, leading to dampness and mould growth. Over time, this moisture weakens the render, causing it to bubble, peel, or crumble. Proper sealing and drainage systems are crucial to prevent water ingress and protect the render.

Structural Issues

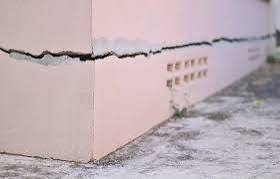

Building Movement

Buildings naturally settle over time, and this movement can create stress on the rendered surfaces. This stress often results in cracks, especially if the render is not flexible enough to accommodate the shifting. Structural issues, such as foundation problems or nearby construction activities, can exacerbate this damage.

Improper Application

The longevity of cement render heavily depends on the quality of its application. Common mistakes include incorrect mix ratios, inadequate curing times, and poor surface preparation. These errors can lead to weak adhesion, cracking, and premature deterioration of the render.

Material Quality and Age

Quality of Materials Used

Using high-quality materials in the rendering process is vital for durability. Substandard cement, sand, or additives can compromise the strength and longevity of the render. Additionally, poor-quality materials are more susceptible to weathering and wear.

Natural Aging

Even with the best materials and application techniques, cement render has a finite lifespan. Over time, it will naturally deteriorate due to exposure to environmental elements and daily wear and tear. Recognising the signs of aging, such as surface erosion or discolouration, can help in planning timely repairs or replacement.

External Impacts

Mechanical Damage

Physical impacts from accidental knocks, vandalism, or nearby construction can damage cement render. Such impacts may result in chips, cracks, or holes, which can worsen if not promptly addressed.

Biological Growth

Moss, algae, and mould growth are common issues in damp or shaded areas. These biological elements not only affect the appearance of the render but can also retain moisture against the surface, leading to further deterioration.

Preventive Measures

Regular Maintenance

Routine inspection and maintenance are crucial for the longevity of cement render. Regularly check for cracks, peeling, or other signs of damage, and address them promptly to prevent more extensive issues. Cleaning the render and removing any biological growth can also help maintain its appearance and durability.

Protective Coatings

Applying protective coatings such as sealants and paints can significantly extend the lifespan of cement render. These coatings provide an additional barrier against moisture, UV rays, and other environmental factors. When choosing protective products, ensure they are compatible with the type of render used on your building and you can also enquire with professionals that do cement render repair in Sydney.

Conclusion

Cement render is a durable and attractive option for building exteriors, but it requires proper care and maintenance to prevent damage. By understanding the various factors that can affect render, from environmental conditions to material quality, you can take proactive steps to protect your property.

Keep an eye for more news & updates on GlamourUer.Com!